Yepamusoro Kudzvanya Kwakazara Welded Bhora Vavhavha yeOiri & Gasi

BAL702

Product Description

IFLOW high pressure yakazara yakazara welded ball valves for offshore applications ndiwo mhinduro dzepamusoro dzeindasitiri yemafuta negasi. Yakagadzirwa uchishandisa chaiyo engineering uye yekucheka-kumucheto tekinoroji, iyo valve yakagadzirirwa kukurira zvakanyanya mamiriro uye inopa isingaenzaniswi kushanda munzvimbo dzemahombekombe. Yakagadzirwa nemhando yepamusoro-simba uye muviri wakazara welded yekusimba uye kuvimbika, zvichiita kuti ive yakanaka kune offshore mashandiro.

Ivhavha yakashongedzerwa neyepamberi yekuisa chisimbiso iyo inovimbisa kuvharika kwakasimba uye kushoma kudonha, nekudaro kunowedzera kuchengetedzwa uye kuchengetedzwa kwezvakatipoteredza kwekumisikidzwa kwemahombekombe. Dhizaini yayo yakaoma uye yakakwirira-kudzvanywa masimba inoita kuti ive yakakodzera kune yakakosha maapplication, ichipa seamless kuyerera kuyerera uye kuita kwakaringana pasi pemamiriro ekumanikidza. Kuvakwa kwakanyatso shizha kunobvisa nzvimbo dzekuvuza, kukupa runyararo rwepfungwa uye nekuona kutendeseka kweiyo offshore oiri uye gasi masisitimu.

IFLOW's high-pressure yakakwenenzverwa bhora mavharuvhu akagadzirirwa kusangana neindasitiri zviyero uye zvinodiwa zvekutonga, kuve nechokwadi chekutevedzera uye kuvimbika mukushanda kwemahombekombe. Yayo compact dhizaini uye inoshanda yekuisa maficha inoita kuti ive inodhura-inoshanda uye yakaderera-yekugadzirisa mhinduro yekumisikidza offshore. Sarudza IFLOW's high-pressure yakazara yakazara welded bhora mavharuvhu kune offshore application uye ruzivo rwemhando yepamusoro, kusimba uye kuita munzvimbo dzinonyanya kudiwa dzemahombekombe.

Features

Product Overview

Iyo mhando inogona kugadzirwa kuti ienderane nechikumbiro chako, nekuvakwa kwemuviri, zvinhu, uye zvekuwedzera maficha akagadziridzwa kuti asangane nemaitiro ako ekuda. Kuve ISO 9023 Certified, isu tinotora nzira dzakarongeka dzekuva nechokwadi chemhando yepamusoro, unogona kuvimbiswa kuvimbika kwakanyanya uye kuisa chisimbiso kuburikidza nehupenyu hwekugadzira zvinhu zvako.

Technical Inodiwa

Kudzvinyirira Kwekushanda: PN20

Kushanda Tembiricha: -10 ℃ ~ 170 ℃

· KUSHANDA ZVAKARE: Mvura, Mafuta uye Steam

Tsanangudzo

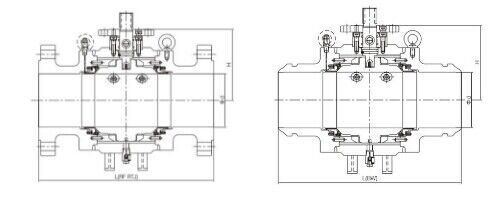

Chigadzirwa wireframe

Dimensions Data

Tsanangudzo

| Zita dhayamita(mu) | NPS6-40 | ||||||

| Nominal pressure (Mpa) | Kirasi150-Kirasi900 | ||||||

| NO | CHIKAMU ZITA | CARBON STEEL | STINESS STELL | ||||

| Zvinhu zvezvikamu | 1 | Muviri | ASTMA105 | ASTMA182 304 | ASTMA182 316 | ASTMA182 304L | ASTM A182 316L |

| 2 | Anti-fire kurongedza | Graphite | |||||

| 3 | Seat | PTFE/NYLON/PEEK/PPL | |||||

| 4 | Mhete yechigaro | ASTM A105.ENP | ASTMA182 304 | ASTMA182 316 | ASTMA182 304L | ASTM A182 316L | |

| 5 | O-ring | VITON | |||||

| 6 | Spring | 17-7PH | |||||

| 7 | Bonnet | ASTMA105 | ASTMA182 304 | ASTMA182 316 | ASTMA182 304L | ASTM A182 316L | |

| 8 | Sealant jekiseni valve | Zvikamu zvakasanganiswa | Zvikamu zvakasanganiswa | Zvikamu zvakasanganiswa | Zvikamu zvakasanganiswa | Zvikamu zvakasanganiswa | |

| 9 | Tarisa vharafu | Zvikamu zvakasanganiswa | Zvikamu zvakasanganiswa | Zvikamu zvakasanganiswa | Zvikamu zvakasanganiswa | Zvikamu zvakasanganiswa | |

| 10 | Bhora | ASTM A105.ENP | ASTMA182 304 | ASTMA182 316 | ASTMA182 304L | ASTM A182 316L | |

| 11 | Shandisa gasket | PTFE | |||||

| 12 | Sliding bearing | Metal+PTFE | Metal+PTFE | Metal+PTFE | Metal+PTFE | Metal+PTFE | |

| 13 | Pin | ANSI 1035 | ANSI 1035 | ANSI 1035 | ANSI 1035 | ANSI 1035 | |

| 14 | Bearing hold | ASTM A105.ENP | ASTMA182 304 | ASTMA182 316 | ASTMA182 304L | ASTM A182 316L | |

| 15 | Chisimbiso gland | ASTM A105.ENP | ASTMA182 304 | ASTMA182 316 | ASTMA182 304L | ASTM A182 316L | |

| 16 | Simba rekutakura | PTFE | |||||

| 17 | Stem | ASTM A182 F6a | ASTM A182 304 | ASTMA182 316 | ASTMA182 304L | ASTM A182 316L | |

| 18 | Flat kiyi | ANSI 1045 | ANSI 1045 | ANSI 1045 | ANSI 1045 | ANSI 1045 | |

| 19 | Simba rekutakura | PTFE | |||||

| 20 | Anti-moto gasket | SST+Graphite | |||||

| 21 | Connection plate | ASTMA105 | ASTMA182 304 | ASTMA182 316 | ASTMA182 304L | ASTM A182 316L | |

| 22 | Socket head cap screw | A193 B7M | A320 B8 | A320 B8M | A320 B8 | A320 B8M | |

| 23 | Packing | Graphite | |||||

| 24 | Packing gland | ASTM A182 F6a | ASTM A182 F6a | ASTM A182 F6a | ASTM A182 F6a | ASTM A182 F6a | |

| 25 | Anti-static valve | Zvikamu zvakasanganiswa | Zvikamu zvakasanganiswa | Zvikamu zvakasanganiswa | Zvikamu zvakasanganiswa | Zvikamu zvakasanganiswa | |

| 26 | Air release valve | Zvikamu zvakasanganiswa | Zvikamu zvakasanganiswa | Zvikamu zvakasanganiswa | Zvikamu zvakasanganiswa | Zvikamu zvakasanganiswa | |

| 27 | Drainage valve | Zvikamu zvakasanganiswa | Zvikamu zvakasanganiswa | Zvikamu zvakasanganiswa | Zvikamu zvakasanganiswa | Zvikamu zvakasanganiswa | |

| Applicalbe sevhisi mamiriro | Midhiya inoshanda | Chipfunga chemvura, oiri, gasi, liquefed, gasi, gasi rechisikigo, nezvimwewo | Nitric acidAcetic asidhi | Acetic acid | Yakasimba Oxidizer | Urea | |

| Applicalbe tembiricha | 120℃(PTFE).≤80℃(NYLON),≤250℃(PEEK), ≤250℃(PPL) | ||||||

| Kugadzira uye kugadzira | API 608,API6D | ||||||

| Kutarisana nechiso | ASME B16.10, API 6D,JIS B2002 | ||||||

| Mhando yekubatanidza | Flange | ASME B16.5/ASME B16.47 | Bult welding | ASME B16.25 | |||

| Pressure test | API598. API6D | ||||||

| Transmission mode | Manual, worm uye worm gear transmission, pneumatic, magetsi | ||||||

Dimensions data(mm)

| Pressure rating | Nominal Diameter | d | Flange | Bult welding | H | Huremu(kg) | |||

| Kirasi | NPS | DN | L(RF) | L(RTJ) | L(BW) | WE | RF | ||

| 150 | 6″ | 150 | 150 | 394 | 406 | 457 | 225 | 185 | 220 |

| 8″ | 200 | 201 | 457 | 470 | 521 | 258 | 250 | 290 | |

| 10″ | 250 | 252 | 533 | 546 | 559 | 310 | 400 | 430 | |

| 12″ | 300 | 303 | 610 | 622 | 635 | 350 | 550 | 620 | |

| 14″ | 350 | 334 | 686 | 699 | 762 | 382 | 820 | 900 | |

| 16″ | 400 | 385 | 762 | 775 | 838 | 421 | 1100 | 1220 | |

| 18″ | 450 | 436 | 864 | 876 | 914 | 468 | 1400 | 1550 | |

| 20″ | 500 | 487 | 914 | 927 | 991 | 510 | 1750 | 1950 | |

| 24″ | 600 | 589 | 1067 | 1080 | 1143 | 592 | 2800 | 3050 | |

| 26″ | 650 | 633 | 1143 | / | 1245 | 635 | 2900 | 3250 | |

| 28″ | 700 | 684 | 1245 | / | 1346 | 675 | 3400 | 3700 | |

| 30″ | 750 | 735 | 1295 | / | 1387 | 723 | 4800 | 5300 | |

| 32″ | 800 | 779 | 1372 | / | 1524 | 751 | 5500 | 6000 | |

| 36″ | 900 | 874 | 1524 | / | 1727 | 858 | 7550 | 8370 | |

| 40″ | 1000 | 976 | 1753 | / | 1956 | 930 | 10290 | 11320 | |

| 300 | 6″ | 150 | 150 | 403 | 419 | 457 | 225 | 185 | 230 |

| 8″ | 200 | 201 | 502 | 518 | 521 | 258 | 250 | 300 | |

| 10″ | 250 | 252 | 568 | 584 | 559 | 310 | 400 | 460 | |

| 12″ | 300 | 303 | 648 | 664 | 635 | 350 | 550 | 670 | |

| 14″ | 350 | 334 | 762 | 778 | 762 | 382 | 820 | 1000 | |

| 16″ | 400 | 385 | 838 | 854 | 838 | 421 | 1100 | 1320 | |

| 18″ | 450 | 436 | 914 | 930 | 914 | 468 | 1400 | 1650 | |

| 20″ | 500 | 487 | 991 | 1010 | 991 | 510 | 1750 | 2000 | |

| 24″ | 600 | 589 | 1143 | 1165 | 1143 | 592 | 2800 | 2550 | |

| 26″ | 650 | 633 | 1245 | / | 1245 | 635 | 2900 | 3300 | |

| 28″ | 700 | 684 | 1346 | / | 1346 | 675 | 3400 | 3750 | |

| 30″ | 750 | 735 | 1397 | / | 1397 | 723 | 4800 | 5500 | |

| 32″ | 800 | 779 | 1524 | / | 1524 | 751 | 5500 | 6500 | |

| 36″ | 900 | 874 | 1727 | / | 1727 | 858 | 7550 | 8800 | |

| 40″ | 1000 | 976 | 1956 | / | 1956 | 930 | 10290 | 11900 | |

| Pressure rating | Nominal Diameter | d | Flange | Bult welding | General | Huremu(kg) | |||

| Kirasi | NPS | DN | L(RF) | L(RTJ) | L(BW) | H | WE | RF | |

| 600 | 6″ | 150 | 150 | 559 | 562 | 559 | 255 | 250 | 330 |

| 8″ | 200 | 201 | 660 | 664 | 660 | 290 | 340 | 450 | |

| 10″ | 250 | 252 | 787 | 791 | 787 | 320 | 570 | 710 | |

| 12″ | 300 | 303 | 838 | 841 | 838 | 380 | 580 | 1000 | |

| 14″ | 350 | 334 | 889 | 892 | 889 | 410 | 1100 | 1370 | |

| 16″ | 400 | 385 | 991 | 994 | 991 | 435 | 1350 | 1650 | |